News

News

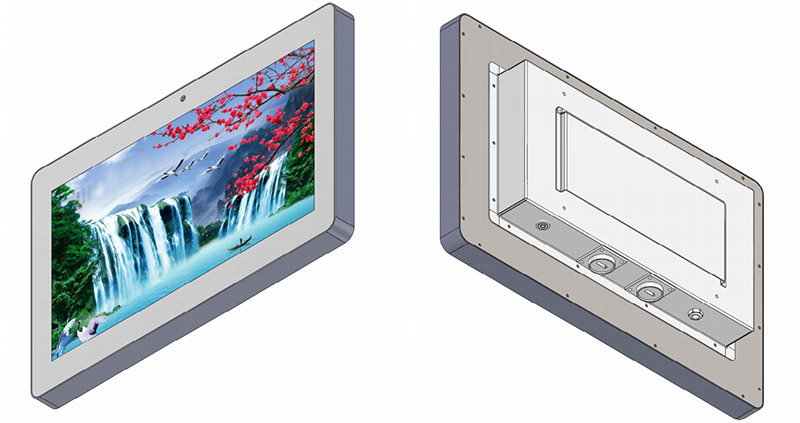

8 advantages of using industrial capacitive touch screen monitor

As we all know, there are several types of touch screens on the market, such as capacitive touch screens, resistive touch screens, infrared touch screens, and surface acoustic wave touch screens. In these methods, capacitive touch screens and resistive touch screens are more popular. The main difference between capacitive screens and resistive screens is that capacitive screens can achieve multi-touch, while resistive screens are one-touch.

This article will introduce the advantages of 8 point industrial capacitive touch screen

1. Technical principle

Capacitive touch screens respond by current, which does not require pressure to generate signals. In simple terms, the screen is divided into blocks, and a set of mutual capacitance modules are set up in each area, all of which work independently, so the capacitive screen can independently detect the touch situation of each area, so capacitive touch screen support multi-touch

For the needs of industrial touch screen monitors, most users will also choose capacitive touch screen. Capacitive touch screens not only support 10-point touch, but also have anti-static anti-interference performance, which makes it more advantageous in scenarios such as power cabinets.

2. Simple calibration

After the industrial capacitive touch screen is produced, the touch screen needs to be calibrated only once or not. Resistive technology requires conventional calibration. After the capacitive touch screen is installed in the industrial touch screen monitor, the touch screen manufacturer will perform a rigorous touch function test to verify that the capacitive touch screen is properly connected to the internal components of the machine.

3. Longer service life

The industrial capacitive touch screen has a longer service life because the components in the capacitive touch screen do not require any movement. In a resistive touch screen, the upper ITO film needs to be thin enough to be elastic so as to bend down to contact the lower ITO film.

4. Less consumption

From the perspective of touch technology, capacitive technology is superior to resistive technology in light loss and system power consumption, so this is also reflected in the advantages of using industrial capacitive touch screen monitor.

5. More convenient for routine operations

When selecting an industrial touch screen monitor, the user needs to consider the application scenario of the device, and choosing a capacitive touch screen or a resistive screen mainly depends on the object of the touch screen. If it is a finger touch, capacitive touch screen is a better choice. If you need a stylus, whether it's plastic or metal, a resistive touch screen can do the job. The capacitive touch screen can also use a stylus, but requires a special stylus to cooperate.

6. Small and medium size equipment is more suitable

For a capacitive touch screen, a large size screen can achieve surface capacitive touch, but currently cannot support gesture recognition. Therefore, industrial capacitive touch screen monitor is now mainly used for 10.1-23.8-inch small and medium-sized touch display devices, such as industrial touch screen monitor, all-in-one industrial touch screen, and can support gesture recognition.

7. Low maintenance costs

Industrial capacitive touch screen monitor due to multi-finger touch, the damage to the screen is very small, and the capacitive technology itself has the characteristics of wear resistance and long life, so the maintenance cost is low when the user is using it,save a lot of operating expenses.

8. More responsive

Based on the technical principle of capacitive touch screen multi-touch, the industrial capacitive touch screen monitor has more than 50 million touches, a response time of less than 15 ms, and a screen error of less than 1%. The screen response similar to the sensor is more sensitive, let users experience better during use

You may also like

EN

EN